EDW (ELECTRO-DEWATERING)

SLUDGE DEWATERING

Having developed, during the last 15 years many applications of electrocoagulation (EC) , the objective of this work done in INTECNA’s Group Laboratories is to find an operationally applicable system to increase the dry substance content during the sludge dehydration process of civil and industrial WWTP.

The biological active sludge of WWT appears as an aggregate of flocs or cells suspended in free water and inside the flocs there is a type of interstitial (or intercellular) water and a type of intracellular water which acts as a layer protective.

Within this layer there are substances defined as EPS (Extracellular Polymers Substances) consisting of polysaccharides and proteins. EPS have a three-dimensional structure with a gelatinous and highly hydrated matrix with large surface area and numerous functional groups (Carboxyl, Phosphoric, Amino and Hydroxyl), which significantly affect the physicochemical characteristics of sludge, such as adhesion, hydrophobicity, sedimentation and dehydration.

EPS contain negative Z potential charged functional and play a specific role precisely in the sedimentation and dewatering properties of the sludge.

Its known, that sludge dewatering is performed for:

- Improve sludge handling properties

- Reduce transportation and disposal costs (reduce sludge volume)

- Reduce the production of landfill leachate

- Making sludge suitable for incineration by increasing its calorific value

The conventional drying techniques are mechanical dehydration (MD) through centrifuges, belt-presses and filter-presses and thermal drying (TD).

The yields in mechanical dehydration are usually in the range of 20 – 30%, this system being capable of eliminating interstitial water, but not intracellular water and therefore, alongside this conventional route, studies are underway to increase this percentage, which especially in large systems it has a very significant impact

The system we have focused on is ELECTRO-DEHYDRATION or EDW, as INTECNA GROUP is already a manufacturer of EC and EDW systems and the basic principles of these technology are extensible for Sludge dewatering process.

EXPERIMENTAL DATA COLLECTION CONDITIONS

The tests were conducted with a cell with a volume of 400 liters equipped with a feed pump and a recirculation pump. CELDAR ™ electrodes used are in inert conductive material sized and designed by IDRIMA.

The electrodes were installed in variable numbers during the tests and the direct current power supply has a potential of 150 Ampere and 50 volts.

Based on the theoretical data, the expectations were as follows:

- INCREASE IN THE WATER VOLUME RELEASED DUE TO THE COLLAPSE OF THE CELL PROTECTION

- COD INCREASING (due to soluble parts increasing into the water)

- REDUCTION OF THE WEIGHT OF THE FILTERED WET FRACTION

- INCREASING IN DRY MATTER IN SLUDGE OF FILTERED FRACTION

The experimental data confirmed all expectations as shown in the table:

DRY STARTING VALUE = FROM 2,5 TO 3,7 %

SAMPLE (Lt) = 4

WATER RELEASED WITHOUT TREATMENT (AVERAGE) Lt = 3,37 - AVERAGE COD : 270 ppm

WATER RELEASED WITH TREATMENT (AVERAGE) Lt = 3,45 (+2,4%) - AVERAGE COD: 420 ppm

WET FILTERED CAKE (AVERAGE) gr = 660

WET FILTERED CAKE (AVERAGE) gr = 540 (-18%)

DRY CONTENT DEWATERED WITHOUT TREATMENT (AVERAGE) gr = 19,5

DRY CONTENT DEWATERED WITH TREATMENT (AVERAGE) % = 25,4 (+30%)

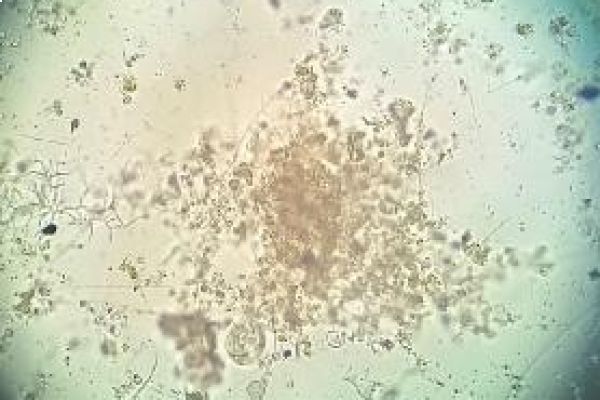

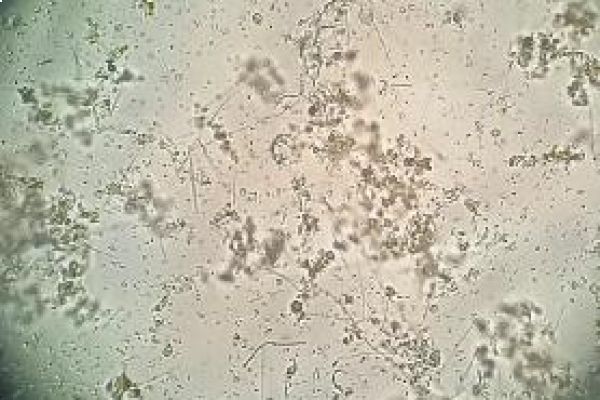

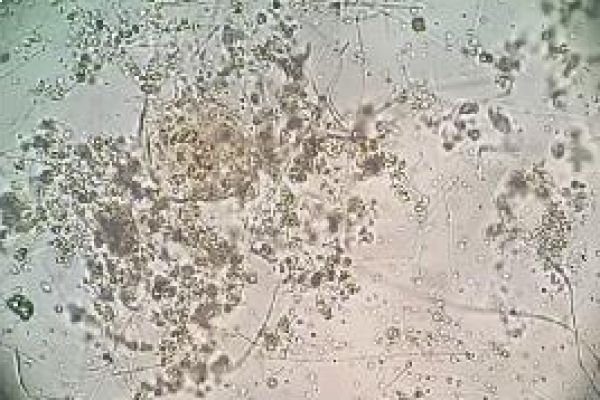

From some microscopic photographs, evident changes in the structure of the sludge can be seen before and after the treatment in the electrolytic cell.

In photos 1 and 2, you can see the untreated sludge.

After the treatment in an electrolytic cell, an almost complete breakdown of the aggregates and cells of the microorganisms is evident. (Photo 3 and Photo 4)

EDW process has therefore a secondary aspect of the treatment which will be the subject of further evaluations , since in addition to the observed increase in dry matter in the dehydration process, there is also a reduction in the bacterial concentration and the disappearance of odors, aspects which in many cases are absolute interest especially in sensitive areas.

CONCLUSIONS

Electrocoagulation (EDW) has a significant effect on the breakdown of cell protection and allows for greater intracellular water release with dry matter increasing more than 30 % compared with conventional methods.

The system is simple and does not require particular plant engineering measures for safety aspects.

The value of the electrical power required is very modest.

The nature of the water obtained during this electrocoagulation EDW process does not have substantial qualitative variations.