Celdar® Technology

Wastewater treatment in bio-diesel production industry

Location: Serbia

PRODUCED WASTEWATER: 15 cubic meter/hour

Typical problems in wastewater: High COD, Oil, High MW Organic compounds

TREATMENT PRINCIPLES AND AIMS

The customer asked us to evaluate the Electrocoagulation for the Treatment of Bio-Diesel Effluent and to be able to drain the treated water into the sewer system.

Another option required was the Zero liquid discharge and therefore the possibility of water recycling with the least amount of consumption possible.

This option is possible using an ELECTROCOAGULATION PLANT since no chemicals are used and therefore the physical and chemical characteristics of the water to be treated have little variation compared to the treated water.

The customer has planned to install a final biological treatment, but asks to be able to avoid oversizing, for reasons of space and especially to be able to eliminate many substances in the pre-treatment that have proved difficult to bio-degradable.

Substantially, the assessment that we can give is that Electrocoagulation can be used as a complementary and preliminary treatment to a biological plant as it is able to remove about half of the soluble COD. This is certainly an advantage, as the subsequent sizing of the biological plant will be reduced.

So, this technique, which is much less expensive than a biological cycle (due to the reduced energy cost), provides a real economic advantage.

The experimental work was done using different types of electrodes in our system to generate a partial oxidation of non-biodegradable substances in the electrolysis cell.

The results were much appreciated

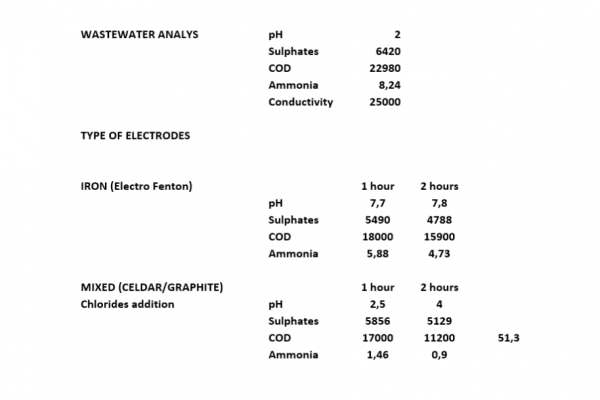

The analytical data are shown in the following table