Celdar® Technology

Emulsion breaking automotive industry

Location: ITALY

PRODUCED WASTEWATER: 20 cubic meter/hour

Typical problems in wastewater: Cutting oil exhausted emulsions separation

TREATMENT PRINCIPLES AND AIMS

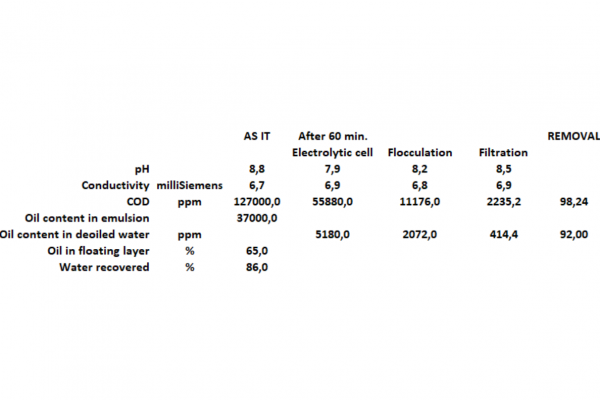

The customer asked us to evaluate the ELECTROCOAGULATION for the emulsion breaking and the main objective of the company that produces about 3000 tons / year of emulsions is to be able to avoid disposal, which has a very high cost and to send the water after the oil separation, to its chemical physical plant.

Another option required was the ZERO LIQUID DISCHARGE and therefore the possibility of WATER RECYCLING with the least amount of consumption possible.

This option is possible using an ELECTROCOAGULATION PLANT since no chemicals are used and therefore the physical and chemical characteristics of the water to be treated have little variation compared to the treated water.

Number of electrodes: 20

Type of alloy: CELDAR

Volt applied: 8

AMPERES: 110

Reaction time: 1 hour

Temperature: 38 °C

Final treatment: Flocculation

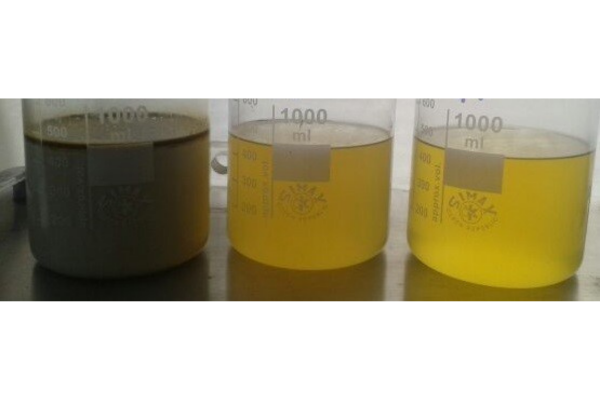

In the electrochemical process of breaking the cutting oil emulsion, during the passage of the current, a floating layer of oil-rich emulsion is removed by means of a skimmer.

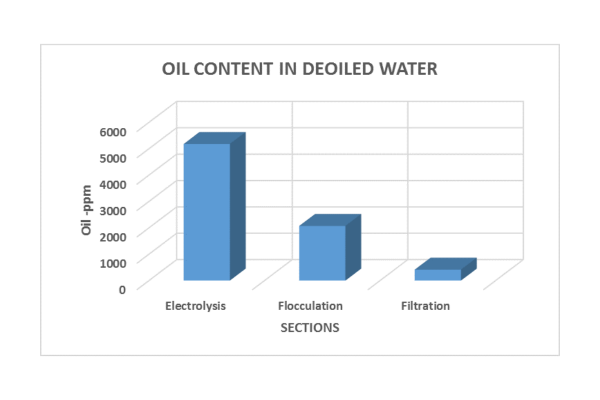

In addition to the electrolysis cell, our plant also features the flocculator and a filtration system. In these sections, the oil content decreases and at the end of the process, the water obtained is treatable in a conventional chemical-physical plant.

The graph shows the analysis of the oil content in the de-oiled water rolex replika