Celdar® Technology

Fluorides removal in lithium battery recovery industry

Location: NORTH EUROPE

PRODUCED WASTEWATER: 40 cubic meter/hour

Typical problems in wastewater: High Fluorides, Sulphates, COD

TREATMENT PRINCIPLES AND AIMS

To design a wastewater treatment plant, the customer asked us to evaluate the ELECTROCOAGULATION for the removal of Fluorides, to be able to avoid corrosion phenomena in installed electrical and mechanical

Another option required was the ZERO LIQUID DISCHARGE and therefore the possibility of reusing the treated water with the least amount of consumption possible.

This option is possible using an ELECTROCOAGULATION PLANT since no chemicals are used and therefore the physical and chemical characteristics of the water to be treated have little variation compared to the treated water.

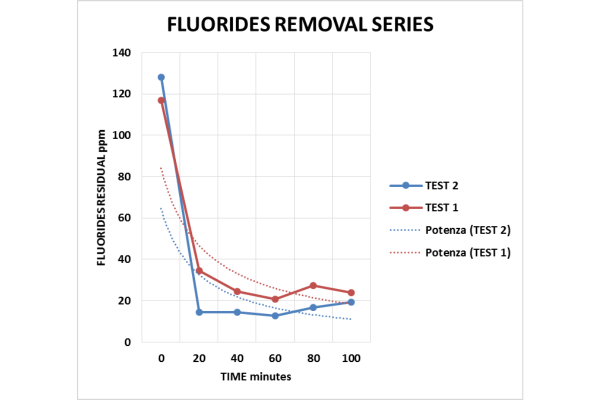

The obtained results and working conditions are below

TYPICAL ANALYSIS PARAMETERS

Achieved results (first image)

ELECTROCOAGULATION PROCESS PARAMETERS

Number of electrodes: 36

Type of alloy: CELDAR

Volt applied: 7

AMPERES: 48

Reaction time: 2 hours

Temperature: 48 °C

Final treatment: Flocculation